Northern Ireland Manitou Dealers

Northern Ireland Manitou Dealers

Over the last 35 years, Northern Lift Trucks, have established themselves as a leading supplier of Manitou construction, agriculture, industrial and access equipment throughout Northern Ireland, Co. Donegal and Co. Sligo. Northern Lift Trucks, based in Lisburn boast an extensive range of top-class machinery including telescopic handlers, excavators, loaders, skid steers, forklift trucks, warehousing solutions and access platforms.

Manitou Telescopic Handlers

Manitou Telehandlers are at the cutting edge of technology and innovation. Their features guarantee you can operate efficiently in optimal conditions of comfort and safety. The entire range of Manitou Telehandlers have been designed to save you time in operation and maintenance. Easy to handle, compact, versatile, ergonomic and safe, these telescopic forklift trucks improve your productivity and make your daily work easier.

The unrivalled features of a Manitou Telescopic Forklift make your material handling operations easier and help to improve the productivity and profitability of your work site by optimising your working time and limiting investment costs. Whether you need a compact machine, a large loading or lifting capacity, you will find the right solution for you, your farm or your construction site in a Manitou Telescopic Handler from Northern Lift Trucks.

What is a Manitou telescopic material handler?

A telehandler, (also known as a telescopic handler or telescopic forklift) is a multi-purpose machine designed for material handling. A telehandler’s purpose is to lift, suspend and move loads across a diverse selection of work sites, environments, and terrains.

Manitou Telehandlers have been engineered for easy and precise operation, comfort and long-lasting performance to maximise productivity in the construction and agriculture markets.

What is the difference between a Manitou forklift and a Manitou telehandler?

Both forklifts and telehandlers lift, place and move heavy loads. The difference is how they do it, forklifts can only lift loads up and down while telescopic handlers feature forward reaching booms that can be fitted with different attachments, enabling it to move a wide range of materials.

What is another name for a Manitou telehandler?

A telescopic material handler can also be called a telehandler, teleporter, reach forklift or telescopic forklift.

What does a Manitou telescopic handler do?

A telehandler is a hugely versatile lifting machine that is often used in the agriculture and construction industries. The telescopic boom can be fitted with a variety of lifting attachments to suit a wide range of jobs on a diverse range of terrains and environments.

What is the best telehandler on the market?

Manitou Telehandlers are based on sixty years of innovation which results in technologically advanced machinery, designed to reduce your cost of ownership. Every Manitou machine is built for power, versatility, and efficiency to make your day-to-day operations as productive as possible.

How much is a new Manitou telehandler?

The price of a new Manitou Telescopic Handler varies depending on your exact requirements and the machine spec. To get a detailed quote, get in touch.

How do I buy a Manitou telehandler?

To buy a Manitou telehandler, get in touch with our sales team. Your Northern Lift Trucks Sales Representative will guide you through our tailor made purchase options to ensure you are shaking on the best deal, the best service and the best support!

Telescopic Handlers for Agriculture

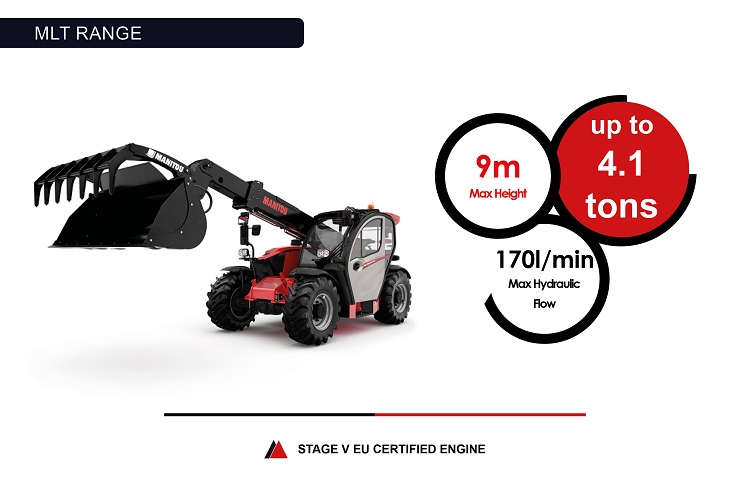

Thanks to the versatility of MLT telescopic handlers, you can perform all the tasks required to manage your farm without having to invest in other handling equipment. Real tool carriers, MLT machines allow you to quickly change attachments to obtain a tailor-made solution that is as close as possible to your needs. MLT telescopic handlers for farmers are available in several high-performance models.

MLT Range: Telehandlers Designed for Farmers

- Comfort

- Visibility

- Easy Access

- Clear Modular Dashboard

- Optimised Fuel Consumption

- Variety of Transmissions

- Performance

- Efficiency

- Profitability

- Choice of Steering Modes

What can you do with an agricultural telescopic handler?

With a diverse range of attachments Manitou Telehandlers for agriculture are ideal for feeding livestock, mucking out, baling, silage distribution and a wide range of general farmyard duties. The most common attachments for use with the MLT range of telescopic handlers are the shear grab, muck grab and road brush.

Who makes the best agricultural telescopic handler?

Manitou Telehandlers are based on sixty years of innovation which results in technologically advanced machinery, designed to reduce your cost of ownership. Every Manitou machine is built for power, versatility, and efficiency to make your day-to-day operations as productive as possible.

What sizes of Manitou Agricultural Telehandler are available?

Manitou MLT Agricultural Telescopic Handlers, are available in a range of sizes. The MLT625-75H is the smallest Agricultural Telehandler in the range, with a lifting capacity of 2,500kg, lifting height of 5.90m and outreach of 3.3m. The largest Manitou NewAg Model is the MLT1041-145 PS+ L, with a lifting capacity of 4,100kg, lifting height of 9.65m and outreach of 6.50m. To view the whole range, click here.

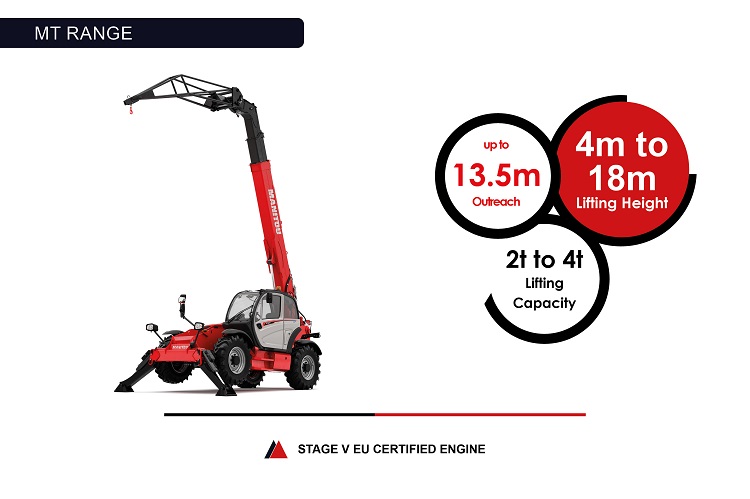

Telescopic Handlers for Construction: High Performance, All Terrain Handling Solutions

Manitou construction telehandlers are based on years of expertise and are designed to outperform other telehandlers on the market. The MT and MHT ranges are especially dedicated to handling heavy and bulky loads, in models from 4 to 18 metres.

Used by the most demanding construction professionals in multiple industries, such as masonry, cladding, tunnelling, roofing, structure, renovation. Their performance makes them indispensable machines for optimising operations (movement/loading, lifting, transporting loads, lifting people) and ensuring perfect safety on site. Manitou construction telescopic forklifts meet all the handling needs of the construction industry. All-terrain, they effectively assist you in your various loading/unloading and load transport operations, whatever the terrain conditions and the constraints of the job. Easy to handle, compact, versatile, ergonomic and safe, these telescopic forklift trucks improve your productivity and make your daily work easier.

MT Range: Construction Handling Solutions

Manitou construction telehandlers offer features that are often unequalled in the material handling market:

- Perfect manoeuvrability

- 3 steering modes: 2 or 4 wheel steering, crab mode

- Interchangeable attachments

- Easy to access, comfortable cab

- Robust, impact-resistant cabs

- 360 degree visibility from the cab

- All-terrain design allowing operation on all types of sites

- Easy handling

- Clear & modular dashboard

- Optimum safety

- Easy to maintain

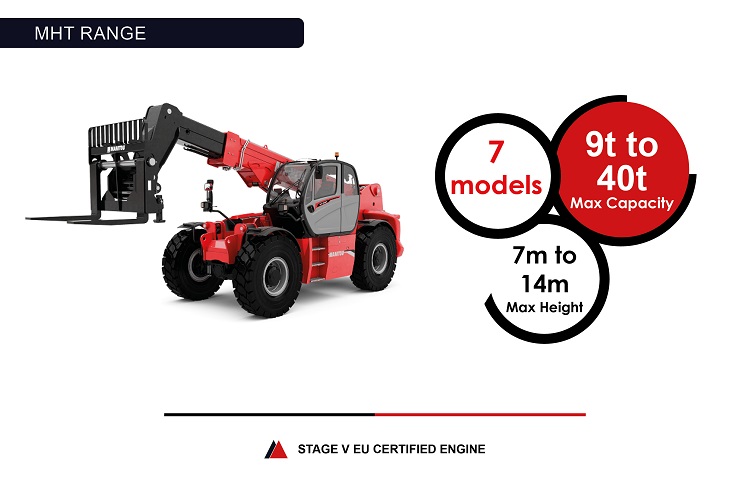

MHT Range: Telescopic Forklifts for Handling Heavy Loads

The MHT telescopic handlers are distinguished by a number of top features and performances:

- High lifting capacity (from 9 to 40 tons)

- 3 steering modes (2 or 4 wheel drive and steering, crab mode)

- Off Road

- High lifting height

- High power

- Ease of use

- Driving comfort

- 360-degree visibility from the cab

- Intuitive controls

- Ergonomic work area

- Optimal safety

What can you do with a Manitou Construction Telehandler?

A telehandler is used for material handling on construction sites; moving, lifting and suspending loads. Suitable for working across a diverse selection of sites, environments and terrains, a construction telehandler can replace a forklift, a crane and access platform with the right attachments.

Who makes the best telescopic handler for construction sites?

The MT & MHT Range of Manitou telescopic handlers meet the requirements of construction professionals who need high-performance, safe and perfectly manoeuvrable handling solutions. All-terrain, these versatile machines adapt to all your loading/unloading, transport/distribution of loads or lifting of people.

Who makes the best telescopic handler for construction sites?

The MT & MHT Range of Manitou telescopic handlers meet the requirements of construction professionals who need high-performance, safe and perfectly manoeuvrable handling solutions. All-terrain, these versatile machines adapt to all your loading/unloading, transport/distribution of loads or lifting of people.

With more than 100, interchangeable attachments including recovery buckets, jib cranes, floating fork aprons, fork spreaders, big-bag handlers and sweepers, Manitou Construction Telehandlers offer great versatility.

Dedicated to large tonnage, MHT machines are particularly used by the extractive industries (mining/refinery/oil) and the public works sector.

Who makes the best telescopic handler for construction sites?

The MT & MHT Range of Manitou telescopic handlers meet the requirements of construction professionals who need high-performance, safe and perfectly manoeuvrable handling solutions. All-terrain, these versatile machines adapt to all your loading/unloading, transport/distribution of loads or lifting of people.

With more than 100, interchangeable attachments including recovery buckets, jib cranes, floating fork aprons, fork spreaders, big-bag handlers and sweepers, Manitou Construction Telehandlers offer great versatility.

Dedicated to large tonnage, MHT machines are particularly used by the extractive industries (mining/refinery/oil) and the public works sector.

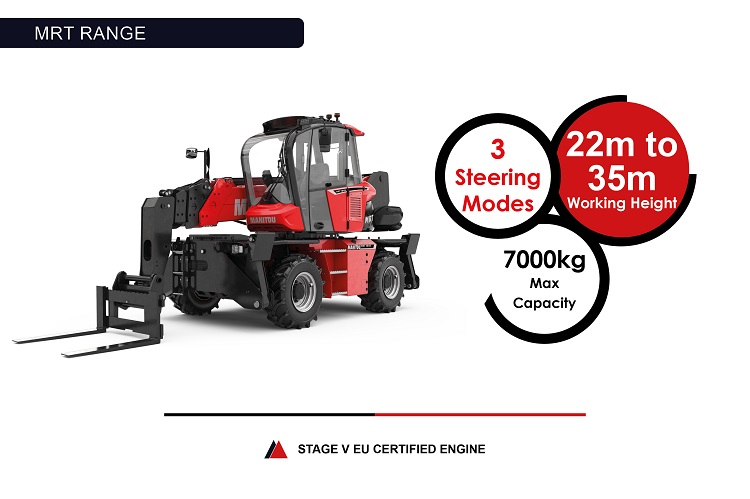

Rotating Telescopic Handlers: All Terrain, 3 – in – 1 Machines: Telescopic Handler, Access Platform and Crane

Rotating telehandlers make your daily work easier, safer, and improve your productivity thanks to their unrivalled performance in the material handling market. Today, two main ranges meet the requirements of professionals: MRT Vision and MRT Vision Plus.

MRT Vision & MRT Vision Plus Range: All Terrain Telescopic Handlers Ideal for Construction and Industrial Applications

The MRT Vision Range has been designed for even greater comfort, safety, visibility, speed and efficiency in everyday use.

- Easy to handle

- intelligent machines

- joystick with recognition system

- ability to handle loads via remote control

- accessible from all 4 sides

- pressurised cabin

- handle loads with 360° panoramic views.

- powerful, safe, precise, stable and versatile

- exceptional visibility

- panoramic cab

- large, ultra-intuitive touch screen that works even while wearing gloves

- additional sound insulation

- radio remote control with integrated display

- Enhanced safety is enhanced with audible and visual indicators

- 360° lighting for working at night

- movement speeds have increased by 30% compared to the previous generation

What is a Rotating Telehandler?

Rotating telescopic handlers, rotary telehandlers or roto’s are a specialist piece of machine handling equipment which are considered a ‘must-have’ machine on most modern construction sites. Rotating telehandlers offer 360 degree reach capability to a number of applications in the construction and industrial sectors, whilst still providing great lifting capacities. The rotating telehandler can be a 3 in 1 machine serving as a crane, telehandler or a powered access solution.

Why choose a Manitou Rotating Telescopic Handler?

Manitou’s range of rotating telehandlers make your daily work easier, safer, and improve your productivity thanks to their unrivalled performance in the material handling market. The most versatile telehandler, a Manitou Rotary Telehandler, is capable of performing the roles of telehandler, crane and access platform, saving you money, time and space on-site.

The design of the latest MRT Vision and MRT Vision Plus Range provides an exceptional 360° visibility from the cab. The precision, visibility and reach of a MRT gives you the ability to move and lift heavy loads without having to move the machine.

What sizes of Manitou Rotating Telehandlers are available?

The MRT Vision performs a working height from 16 to 25 meters (52 to 81 feet), as well as a working offset up to 19.40 meters (64 feet). This range handles maximum lift capacities up to 4,500 kg (9,900 lbs) with 3 steering modes; 2 or 4 wheel steering and a crab mode for angled movements. To view the MRT Vision range, click here.

The MRT Vision Plus Range, are all-terrain rotary telehandlers that can work at heights from 22 to 35 meters (72 to 113 feet). Their maximum lift capacities are 6,000 kg to 7,000 kg (13,200 to 15,400 lbs.) over 25 to 30 meters (82 to 98 feet), with a working offset up to 28 meters (92 feet). To view the MRT Vision Plus range, click here.

Articulated Loaders for Agriculture

Ensure the daily management of your farm in the best conditions thanks to the performance of the MLA articulated loaders. All-terrain, these versatile machines help you to carry out all your operations efficiently from storage of hay bales, towing, animal feeding and cleaning to production handling.

MLA Range: Make Your Daily Work On The Farm Easier

- Robust

- All Terrain 4 Wheel Drive

- Differential Lock

- 45 Degree Articulation

- Parallel Kinematics, Z Kinematics or Telescopic Boom

- Easy to Change Attachments

- 360 Degree Vision

- Comfortable

- Easy to Use

- Optimum Operating Safety

What is an articulated loader?

An articulated loader is simply a loader that swivels on a central point. The pivot steer design makes driving through doors and inside buildings easy as it allows you to drive around obstacles and between objects. This type of loader is best suited to agricultural tasks.

Who makes the best articulated loader?

The MLA range from Manitou offers several models of latest-generation articulated loaders. Offering 3 levels of top-of-the-range finish, these machines make your daily work on your farm easier e.g. Storage of your hay bales, hay bale transport, towing, animal feeding, cleaning, production handling,

The new MLA articulated loaders have been designed to precisely meet the needs of agricultural professionals. Their design is particularly robust, with a high off-road capability (provided by 4-wheel drive and agrarian profile tires) and offers optimum tractive effort (even on muddy ground) thanks to the differential lock on the front and rear axles.

What sizes of Manitou Articulated Loader are available?

You can choose from a wide range of articulated loaders with different dimensions, capacities, and lift heights in addition to a range of options, attachments and finish levels. View all models in the MLA Range, here.

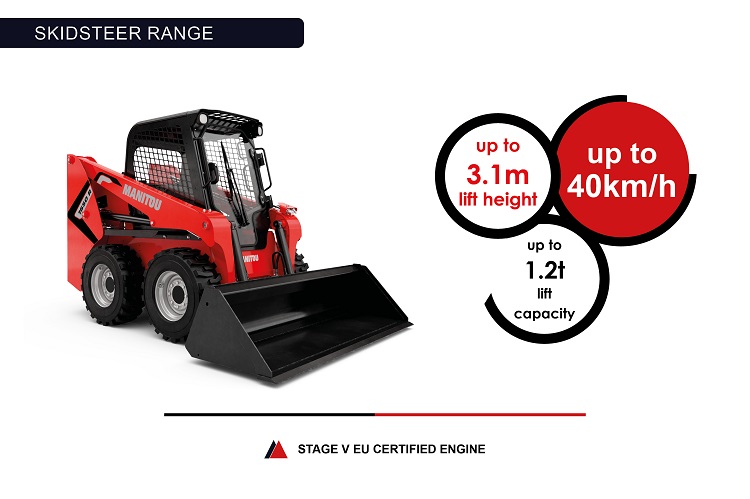

Compact Loaders for Construction, Agriculture, Infrastructure and Landscaping

Manitou compact loaders make it easy to operate in tight or confined work areas combining ease of use, manoeuvrability, power and versatility. Whether you prefer skid or track loaders, our machines allow you to carry out all your tasks in complete safety: transporting pieces of wood or tubes, loading bulk (gravel, sand, grain, mineral supplements, manure), feeding and silage, drilling, raking, digging, digging below ground level.

Skidsteer Loader Range: For All Your Applications

- Single Pin Design

- Low Profile Lifting Arm

- Self-Levelling

- Durable Build

- Excellent Forward Reach

- Level II FOPS/ROPS

- Cab Forward Design

- Radial or Vertical Lift Models Available

- Tracked or Wheeled Models Available

What is a skid steer loader?

Easily manoeuvred, compact in size and compatible with dozens of attachments, skid steer loaders are suitable for a wide range of applications. From moving materials on a construction site or cleaning barns on the farm to landscaping parks, gardens or building roads. The size of skid steer you need depends on the task required and the size of the work site.

Originally designed with a steerable rear wheel the concept evolved to make all 4 wheels fixed. The weight is distributed so that one end is always heavier than the others. When the wheels on the heavier end counter rotate to pivot the loader, the wheels on the lighter end are ‘skidded’ in the direction of the turn.

These compact loaders can be driven on wheels or tracks which can be operated at different speeds to create a skidding effect during operation. The ‘skidding’ motion results in zero-degree radius turns, ideal for working in tight spaces and precision demanding tasks. The skid motion makes these loaders very efficient in working conditions where the ground is uneven.

Who makes the best Skid Steer loader?

Manitou has specialised in the design of loaders and forklifts for several decades. This extensive experience has led to the development of a range of machines which precisely meet the handling requirements of agricultural and construction professionals. With Manitou skid steer loaders, you can easily travel on all types of ground. Designed to be compact, Manitou Skid Steers are ideal for working in congested or cramped work areas.

Not only compact, Manitou skid steer loaders have the advantage of being extremely versatile. A wide range of attachments are available to carry out a diverse range of tasks. Using a skid steer loader for these tasks replaces time consuming manual labour on smaller sites.

Manitou Skid Steer Loaders are manufactured using highly reliable components in a robust and resistant structure. The manufacture and design make Skid Steer Loaders a great investment with a high resale value providing they come with low hours and have been well maintained in-line with manufacturer requirements.

What sizes of Manitou Skid Steer Loader are available?

Skid steer size refers to the size of the frame, the rated operating capacity (ROC) and horsepower (HP). Skid steer loader sizes can be categorised by Small Frame (800kg |under 50hp), Medium Frame (800kg – 1000kg | 50 – 70hp) and Large Frame (1,000kg+ |70hp+). The size you need depends on your job requirements and site dimensions.

Small Frame skid steers are best suited to applications including interior demolition, landscaping or any projects that require moving between narrow spaces or around tight corners. The smaller the loader, the easier it is to transport the equipment between work sites.

Medium Frame & Large Frame Skid Steers are best suited to roadworks and larger scale, more heavy-duty applications.

View all skid steer models for agriculture, here. Click here if you need a wheeled skid steer loader for construction or here if you need a tracked skid steer loader.

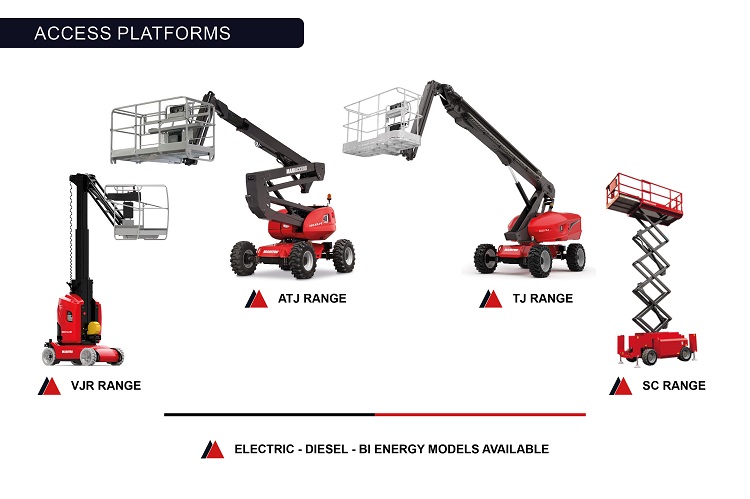

Access Platforms: For Industrial and Construction Professionals

Whether you need to work at height on all-terrain or in an industrial setting, Manitou’s high-performance aerial work platforms are capable of transporting one or more operators in optimal conditions of comfort and safety. Manitou aerial work platforms are available in a wide variety of versions with vertical, articulated, scissor and telescopic boom structures. Offering different working heights (from 8 to 17 meters for the industrial range and from 10 to 28 meters for the all-terrain range), they meet all the requirements of your rental company and MEWP operators.

What is an access platform?

A powered access platform allows employees to safely work at height. There are various models to choose from. Each model has been designed to meet a range of specific on-site requirements, such as indoor/outdoor operation or working in restricted spaces with narrow aisles.

What are the different names for powered access platforms?

Powered Access Platforms can also be called: Work Platforms, Aerial Work Platforms, Mobile Elevated Work Platforms (MEWPs), Cherry Pickers, Boom Lifts, Personnel Lifts or Scissor Lifts.

What access platforms are available from Manitou?

The different types of Powered Access Platforms by Manitou are:

Articulated Access Platforms – ATJ Range: All Terrain for Outdoor Operations

The ATJ range offers aerial work platforms with an articulated structure with jibs. All-terrain, these diesel and electric models are perfectly adapted to outdoor handling operations. Take advantage of their performance and make your daily work easier, whatever your sector of activity.

- 4 Simultaneous Movements

- All Terrain 4 Wheel Drive

- 3 Steering Modes

- Galvanised Basket with Removable Floor

- Off Road

- Optimal Performance

- High Impact Resistant Cover

- Load Sensor & Tilt Sensor

- Full Visibility

- Optimum Operating Safety

Telescopic Access Platforms – TJ Range: Diesel All Terrain Aerial Work Platform

The TJ range of Telescopic boom lifts feature an extendable arm that can reach varying heights. Unlike an articulated boom lift, the telescopic boom has a straight arm that is attached to a freely rotating turntable.

- 4 Simultaneous Movements

- All Terrain 4 Wheel Drive

- 3 Steering Modes

- Telescopic Jib

- Turret

- Optimal Performance

- High Impact Resistant Cover

- Load Sensor & Tilt Sensor

- Full Visibility

- Optimum Operating Safety

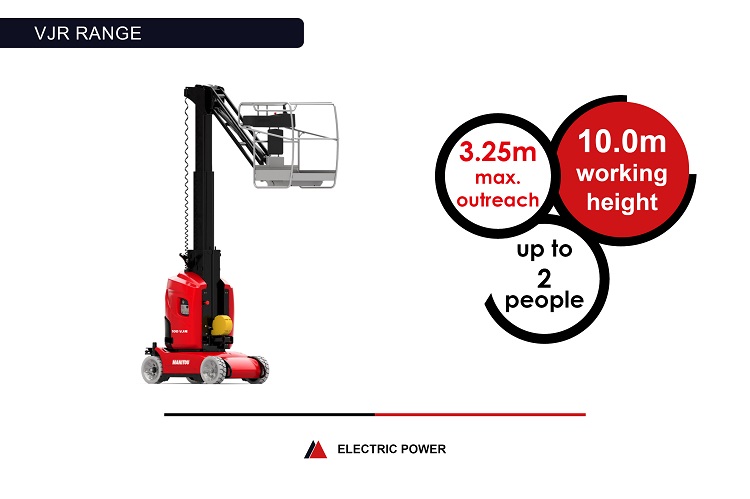

Vertical Mast Access Platforms – VJR Range: Compact Electric Work Platform

The VJR vertical mast aerial work platform is characterised by its high compactness and perfect manoeuvrability. With these features, it is the ideal solution for working at heights in cramped spaces, whether in warehouses or outside your industrial sites. Save time in your maintenance and handling operations thanks to the VJR electric aerial work platform designed by Manitou.

- Compact

- Manoeuvrable

- Telescopic Jib

- Mast with Telescopic Boom

- Turret with 360o Rotation

- Basket for 2 Operators

- Driveability

- High Performance Battery

Scissor Lift Access Platforms – SC Range: Scissor Lifts with Combustion Engine

Designed by Manitou, these aerial work platforms have all the necessary features to facilitate your work and ensure maximum safety conditions for operators. With a capacity for up to 4 operators, SC scissor lifts make your operations at height safe, whatever your business constraints. Electric Models are also available in the SEC Range of Scissor Lifts.

- Maximum Safety

- Non-Slip Floor

- Tilt & Descent Alarms

- Easy To Use

- Compact Design

- All Terrain

- Versatile

- Easy to maintain

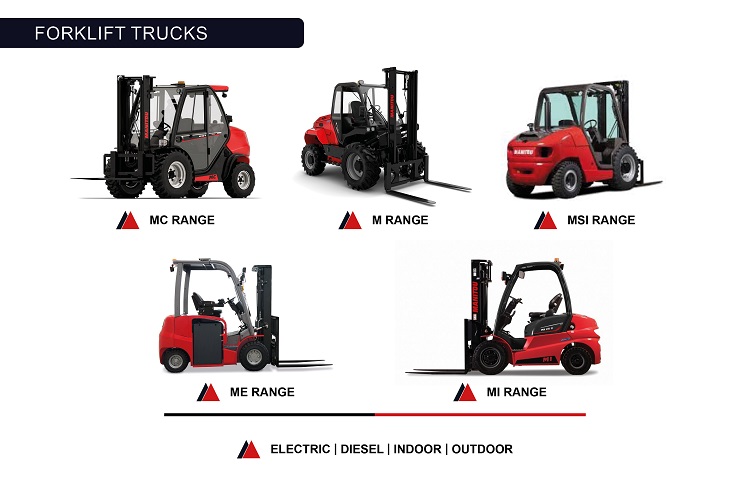

Manitou Masted Forklift Trucks for Industrial, Construction and Agricultural Trades

As the inventor of the first all-terrain forklift trucks, Manitou offers the most efficient forklift trucks on the material handling market. Various ranges meet the requirements of all sectors: agriculture, construction, warehousing and industry.

There are a wide range of Manitou forklifts available:

With a Manitou Forklift, these handling solutions all you to load/unload and/or lift loads efficiently and quickly outdoors and/or indoors, depending on the model, in optimal conditions of comfort and safety. The team at Northern Lift Trucks can help you at any time to choose a forklift truck model suited to your requirements.

Who uses a forklift?

Forklifts are used by many diverse sectors, such as manufacturing, equipment distribution, foods industries and waste management as well as professionals in agriculture and construction industries.

What are the different size forklifts?

Forklifts are available in a variety of lengths, widths, mast heights and lifting capacities.

What is a forklift designed to do?

A forklift is designed to lift and move materials over short distances.

What categories of forklift are there?

Manitou now offers you a wide range of ranges: all-terrain forklift trucks (MC, M); electric (ME), internal combustion (MI) and hydrostatic transmission (MSI) forklift trucks particularly adapted to rougher terrain applications.

What is the difference between a reach truck and forklift?

On a counterbalance forklift, the forks stick out from the front of the vehicle and there are no protruding arms or legs; meaning the truck can be manoeuvred right up close to the racking or location of the load. A reach truck takes its name from the machine’s ability to ‘reach’ out further than its stabilising legs.

How do I choose a forklift?

When selecting the right forklift, the primary criteria are the load capacity, the lift height, the fuel type and the tyre composition:

Lift Height

How high do you need to lift your loads? If you need to load/unload from trailers, pay attention to the lowered mast height of the forklift.

Capacity

What is the maximum weight you need to lift? It’s important to buy a forklift that can handle more than your heaviest load. Keep in mind that attachments will reduce your forklift’s capacity. The most common forklift capacities are:

1000kg or less | 1,000 – 3,000kg | 3,000 – 3600kg | 3,600kg – 5,550kg | 5,500 – 8,000kg | 8,000kg +

Fuel – Electric or Internal Combustion

IC forklifts use traditional engines that run on different types of fuel (CNG, diesel, gas, or liquid propane). Electric forklifts are powered by batteries. If you handle food, you’ll likely need an electric forklift to adhere to emission requirements. However, many applications that once used IC forklifts are finding that electric conversion saves both time and money.

What kind of forklift do I need?

Important factors to consider are where you are using the forklift; Will it be used indoor or outdoor or both? How wide are the aisles and doorways? Will it be used on concrete or rough terrain?

It is also important to work out how many hours per day and how many hours per week you will use the forklift.

What type of forklift is best for indoor use?

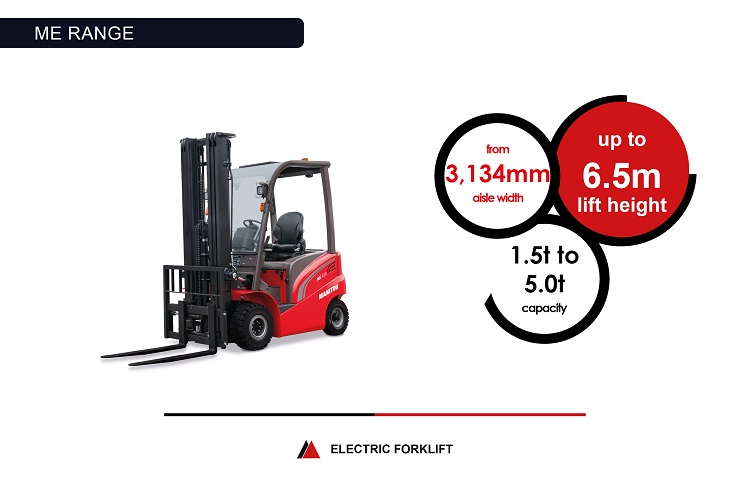

The best forklift for indoor use, such as warehouses is a Manitou ME electric forklift.

What type of forklift would you use in a confined space?

The type of forklift best suited to use in confined spaces is a Manitou ME electric 3 wheeled forklift.

ME Range: Electric Trucks for All Your Industrial Applications

- Easy to Use

- Easy to Maintain

- Easy to Access

- Comfortable

- Secure

- Robust

- Versatile

MI Range: Internal Combustion Mast Trucks with Gas or Diesel Engines

The MI industrial range offers 26 models of internal combustion mast trucks. Offering different lifting capacities (from 1.5 to 10 tons) and different lifting heights (from 6.0 to 6.5 metres), these forklifts help you to carry out all your outdoor and/or indoor handling operations efficiently. MI masted forklift trucks are available with gas or diesel engines. They are particularly recommended for logistics, metallurgy, wood processing, food processing, distribution and the environment.

- Easy to Use

- Easy to Maintain

- Easy to Access

- 3 Mast Types Available

- Optimum Safety

- Robust

- Customisable & Versatile

What is an industrial forklift?

An industrial forklift is designed for lifting and transporting loads in more arduous conditions i.e. builder merchants.

What is the maximum weight a forklift can carry?

The maximum weight a Manitou Industrial Forklift can carry is 10,000kg (model number MI100).

How long does an industrial forklift last?

The length of time an industrial forklift will last will depends on the application it has been used for and how well it has been maintained.

MSI Range: The first Semi-Industrial Forklift on the Market

The performance of MSI machines, their stability and versatility make them suitable for various sectors of activity: sawmills, paper and beverage industry, recycling of industrial and automotive waste, manufacture and distribution of palletised or bulk materials and port activities.

- Versatile

- Compact

- Short Turning Radius

- Millimetre Accuracy

- Robust

- Reliable

- Optimum Visibility

Manitou Truck Mounted Forklift: The Handling Solution for your Deliveries

Manitou Truck-mounted Forklifts have been designed to provide an additional service for material carriers. Allowing you to work in complete autonomy, they help you serve your customers and deliver materials to the last meter, in the best conditions of safety. In less than a minute, our truck-mounted forklifts are ready to load/unload all types of deliveries. The Manitou brand offers material-handling machines equipped with a telescopic boom (TMT) or a mast (TMM). The range of truck mounted forklifts brings you extra service to the last mile of delivery and optimise your logistics operations.

What is a Truck Mounted Forklift?

Truck Mounted Forklifts are forklifts which are attached to the back of your lorries or trailers. It is the handling solution for your deliveries. Regardless of the type of load or application (construction, deliveries to private individuals, events, etc.), you will find the solution in the Manitou Truck Mounted Forklift range.

Mobile and powerful, the truck mounted forklift is always available to get as close as possible to the goods in challenging conditions. In less than a minute, your forklift is ready to load and/or unload any kind of load. The operator can effortlessly reposition it to move to the next destination.

What are the different types of Manitou Truck Mounted Forklift?

What are the advantages of a Manitou Truck Mounted Forklift?

Compared to industrial forklifts, truck-mounted units are lighter and more compact, and this makes them more manoeuvrable. Manoeuvrability and compactness is essential for accessing unloading locations that are too congested for bigger load-carrying equipment such as urban areas with limited access and construction sites with narrow spaces.

Due to their size and design Truck Mounted Forklifts, can place pallets and other material anywhere and do not require a traditional loading and unloading dock.

Truck Mounted Forklifts are mounted on the rear of a truck, so they don’t take up valuable loads pace on the truck bed itself. Truck Mounted Forklifts improve productivity and cost efficiency of every delivery, because the 2-in-1 equipment can be operated by the same employee who can handle loading, transportation, and unloading door-to-door.

They offer a value added service for any delivery business. When using a Truck Mounted Forklift, manual offloading of heavy materials is no longer required, thereby reducing risk of accidents.

Warehousing Solutions: Optimise Your Logistics and Warehousing Operations with a Range of Pallet Trucks, Stackers and Order Pickers

Manitou warehousing solutions offer performance, versatility and safety combined with robustness, ease of use and ergonomics. Choose from our range of Manitou Warehousing Equipment to save time and improve the productivity of your warehouses every day.

Manitou’s range of storage and warehousing equipment include:

EP Range: Powerful Pallet Trucks to Move Pallets Over Short Distances.

The EP range offers several models of electric pallet trucks. Offering different load capacities depending on the model, they have been designed to adapt to a wide variety of warehouse applications. Use them to move your heavy-duty pallets safely within your warehouses and storage areas. ideal solutions for moving pallets easily and safely. They have been specially designed to handle loads in light flows over short distances indoors.

The EP range offers pallet trucks with different load capacities. Developed according to Manitou’s extensive experience in handling solutions, this warehouse equipment guarantees perfect efficiency and manoeuvrability for logistics specialists.

Two versions of EP electric pallet trucks are available.

- Ride-on pallet trucks: these models are equipped with a transport platform allowing the driver to move around with the machine.

- Pedestrian pallet trucks: these models are manual pallet trucks with electric power assistance.

The EP ranges provide a precise response to the needs of logistics transport professionals and warehouses. The use of these small lifting machines is particularly recommended in warehouses, supermarkets and sales areas.

With EP pallet trucks you can improve the productivity of your storage area and optimise the transport of your pallets and loads. Their robust design and safety system make them indispensable tools for your team.

- Move and store pallets from 1500kg to 5000kg

- Efficient

- Reliable

- Easy to Use

- Manoeuvrable

- Safe

- Suitable for all types of industrial applications.

What is a Pallet Truck?

A pallet truck is small material handling equipment equipped with two forks. Designed to transport pallets (or various loads), it can be electrically or manually operated and offers different load capacities depending on the model.

- What are pallet trucks used for?

Pallet trucks are used to transport pallets and palletised loads, typically in a warehouse setting.

- What is another name for a pallet truck?

Pallet trucks are also called ‘Pump Trucks’ or ‘Pallet Jacks’.

- What is the difference between a pallet truck and forklift?

A pallet truck is designed to transport loads, usually over short distances. A forklift can transport a wider range of heavier loads and lift these loads to height.

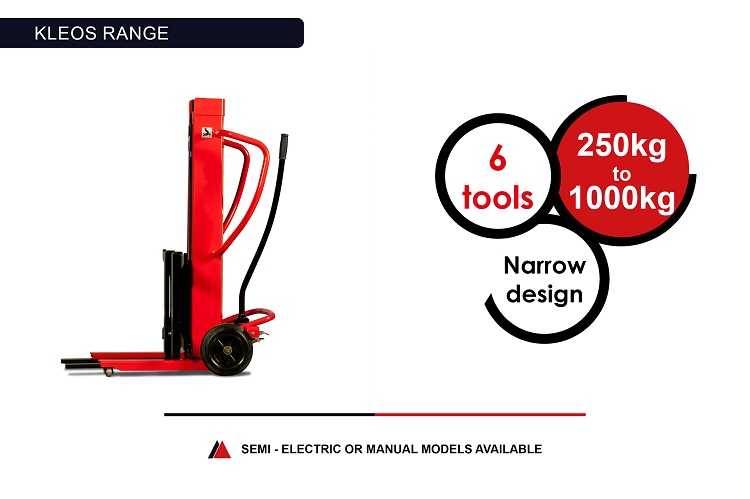

Manual or Semi- Electric Stackers – Kleos Range: Ideal for lifting, stacking or storing goods at height

Capable of handling loads from 250 to 1000 kg, these high-performance machines facilitate the stacking of your stock of goods whatever your activity.

KLEOS manual and semi-electric stackers are designed for warehousing work and logistic transport. Compact, ergonomic, they are real allies in daily use to transport pallets, lift loads, stack them accurately over short distances or improve ergonomics at the operator’s workstation.

Manitou guarantees perfectly robust handling solutions. Innovative and reliable, the KLEOS range allow you to work in optimal conditions of comfort and safety.

In terms of performance, these stackers have all the necessary features to carry out all light handling operations efficiently and quickly. All the more so with their 6 interchangeable tools that allow them to be versatile.

KLEOS stackers are one of the most widely used manual and semi-powered material handling equipment in warehouses. Combining compactness, performance, safety and speed, they are indispensable for all professionals in the industry. Equip your sites with these high-performance models to save time in your preparations and improve the productivity of your employees!

- Compact

- Ergonomic

- Reliable

- Handle Loads from 250kg to 1000kg

What is a warehouse stacker?

Warehouse stackers are devices for lifting, stacking and storing loads at height. They are particularly useful for storing goods and preparing orders. Unlike pallet trucks, stackers therefore allow you to handle loads in a high position: different lifting heights and load capacities are offered depending on the model.

What are stackers used for?

Stackers are often multi-purpose equipment. Compatible with various accessories, they allow you to carry out several handling, warehousing and storage operations in your warehouses and industrial sites.

Manual stackers can handle boxes, containers, pallets, drums, tools, coils and rolls etc. Electric stackers usually have higher load capacities and are able to transport pallets, loads or bulky packages up to several metres high.

What is an electric stacker?

Electric stackers from Manitou have a relatively similar structure to the manual models: two forks and a vertical mast allow the handling of loads. However, these devices have a motor and a battery that automates the lifting device.

What are the different types of warehouse stacker?

Both manual and electric stackers are currently available on the market.

Manitou offers a large number of manual stackers: the Kléos range includes all our references. These stackers are compatible with 6 interchangeable tools.

Manitou electric stackers are part of the Stacky range.

In addition to conventional electric stackers, Manitou offers you electric mast stackers (ES range). These devices can handle loads from 1000 to 3000 kg. The height of their masts is between 1.5 and 5.40 metres. The ES electric stackers are also available in a framing beam version (allowing the picking up of pallets and closed loads) and an initial lift version (ideal for working on uneven ground or slopes).

How do you use a manual pallet stacker?

Manual stackers are composed of two forks mounted on rollers and a vertical mast. The lifting of the load is carried out by means of a hydraulic pump with lever: the lifting is carried out with precision by lateral movements of the lever. An operator is required to operate the lifting device.

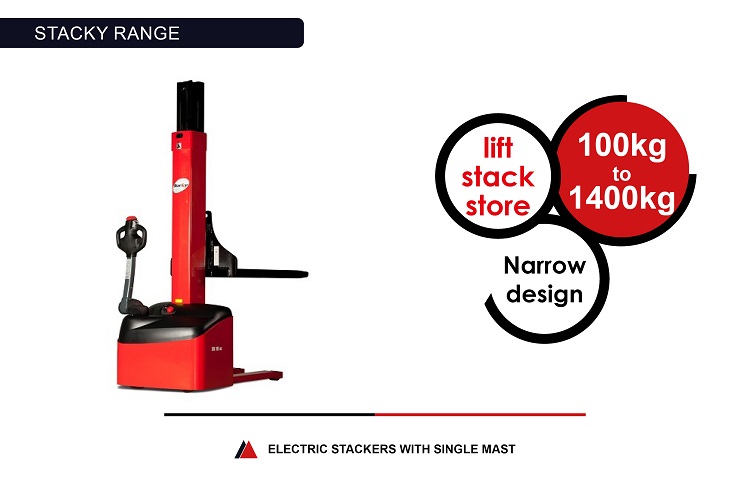

Electric Stackers – Stacky Range: Equipped with a Single Mast, Ideal for small pallets

Manitou has a solid know-how in the design of handling equipment. Based on this expertise, our teams have designed electric stackers that are manoeuvrable, versatile and high-performance: the STACKY range.

The STACKY equipment helps you to carry out the stacking of your stocks of goods. Whether you want to lift, stack or store loads at low heights, our machines meet your needs.

The range offers stackers with a load capacity from 1000 to 1400 kg, to facilitate your warehouse work, logistical transport over short distances and ergonomics at the workplace. Compact and easy to use, they can operate in all areas of your warehouse, including confined and difficult to access spaces.

Electric stackers are equipped with a single mast and can be completed with several easily interchangeable tools, providing a solution precisely adapted to your needs, whatever your activity.

The STACKY range guarantees particularly resistant handling equipment. Reliable and sturdy, it allows you to operate efficiently and safely and has all the necessary performance to ensure ergonomic use.

Versatile, the STACKY models are also an aid to production. Their characteristics make them electric stackers very much used by storage professionals. Combining compactness, performance, safety and reliability, they are ideal for improving your productivity and saving you time on a daily basis.

- Easy to use

- Lifting capacity from 1000 to 1400 kg

- Compact equipment easy to transport, move and store

- Versatility ensured by the possibility to easily change tools

- Perfect manoeuvrability

- High handling accuracy

- Rugged and resistant design

- Safe movement of loads and pallets

Northern Lift Trucks: Your Hire Industry Partner

Northern Lift Trucks position as the provider of Manitou Machinery in Northern Ireland, is further strengthened by NLT’s successful long-term relationships with the NI Hire Industry. NLT offer a wide variety of high quality and versatile machinery. The performance of Manitou machinery partnered with the reliability of NLT’s service ensures that adding any Manitou to your hire fleet will be a guaranteed, dependable income generator.

Manitou For Agriculture

Agriculture throughout Northern Ireland and Co. Donegal is a large and diverse industry. Manitou have a strong reputation for building the right machines to suit your demanding tasks and with their extensive range of attachments they can provide you with a Swiss army knife of tools for your applications.

Manitou For Construction

Construction sites are among the most challenging working conditions, staff must contend with the weather, dust and deadlines to name a few. Manitou recognises that safety, compactness and precision are essential to the successful running of your sites.

With a focus on easy to use machinery, your operators can be immediately productive as it is quick to master. The compactness and the manoeuvrability of the Manitou telehandlers, rotating telehandlers and access platforms makes them suitable for confined sites or in urban areas. The Manitou range of construction machinery can be used on any terrain; in addition their high ground clearance as well as their driving wheels allow you to develop in areas that are difficult to access and clear resulting obstacles.

Manitou For Industry

Do you work in an industry that requires reliable and high-performance handling solutions?

Manitou offer a wide range of solutions specifically adapted to your needs and constraints of a wide variety of industries. Manitou’s range of Industrial and Warehousing Equipment machinery allow you to save time for any type of activity (handling tyres, cylinders etc.) in complete safety and increase productivity.

Whether your needs are related to issues of height, performance, compactness or all these criteria, just contact us so we can show you the solutions that can increase your productivity.

About Manitou

Since Northern Lift Trucks became Manitou Dealers in 1985, the Manitou brand has gone from strength to strength throughout Northern Ireland and Co. Donegal.

Manitou pride themselves on technologically advanced machinery, designed to reduce your cost of ownership. Every Manitou machine is built for power, versatility and efficiency to make your day-to-day operations as productive as possible.

Manitou machinery began with the world’s first compact forklift, based on an idea by Marcel Braud in 1958.

Having established themselves as the provider of world class industrial masted forklift trucks, the

Manitou Telescopic Handler entered the market in quick succession. Today, the Manitou range of Telescopic Handlers, include Manitou’s Rotating Telescopic Handlers and Heavy Telescopic Handlers.

Manitou reached new heights in 1995, with the launch of their first aerial work platform, supplying access and handling solutions worldwide.